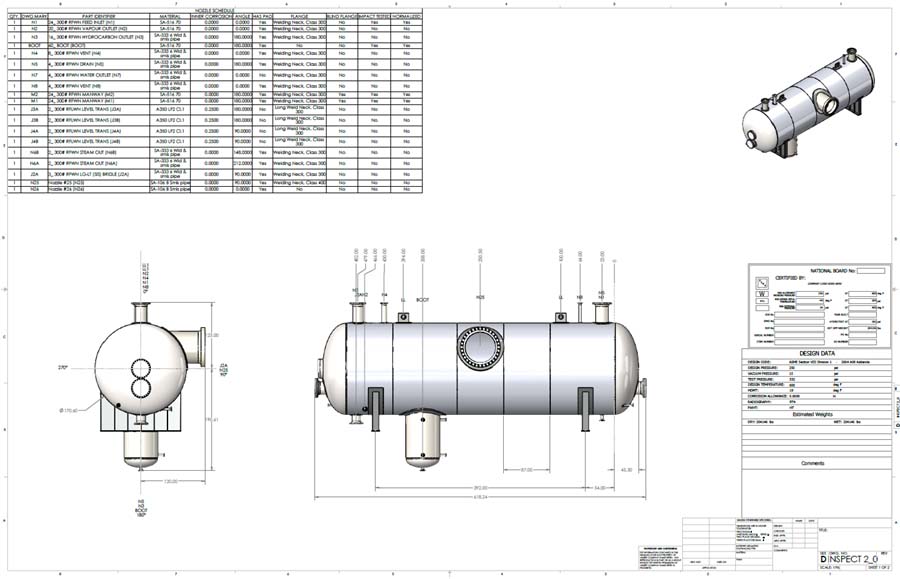

During the manufacturing, the Pressure vessel has to pass a series of Hydrostatic tests. As the mathematical calculation of pressure vessel becomes tedious, graphical based software PV Elite was used for analysis on shell, head, nozzle and saddle supports. Auto CAD is used for drafting the scaled construction drawing of pressure vessel. In here, pressure vessel is a horizontal pressure vessel. The main purpose is to design a pressure vessel according to company requirements and analyzing the pressure vessel using PV Elite with reference to the ASME Sec.VIII Division1 Codes and standard. For any pressure vessel design, primary consideration is its safety.

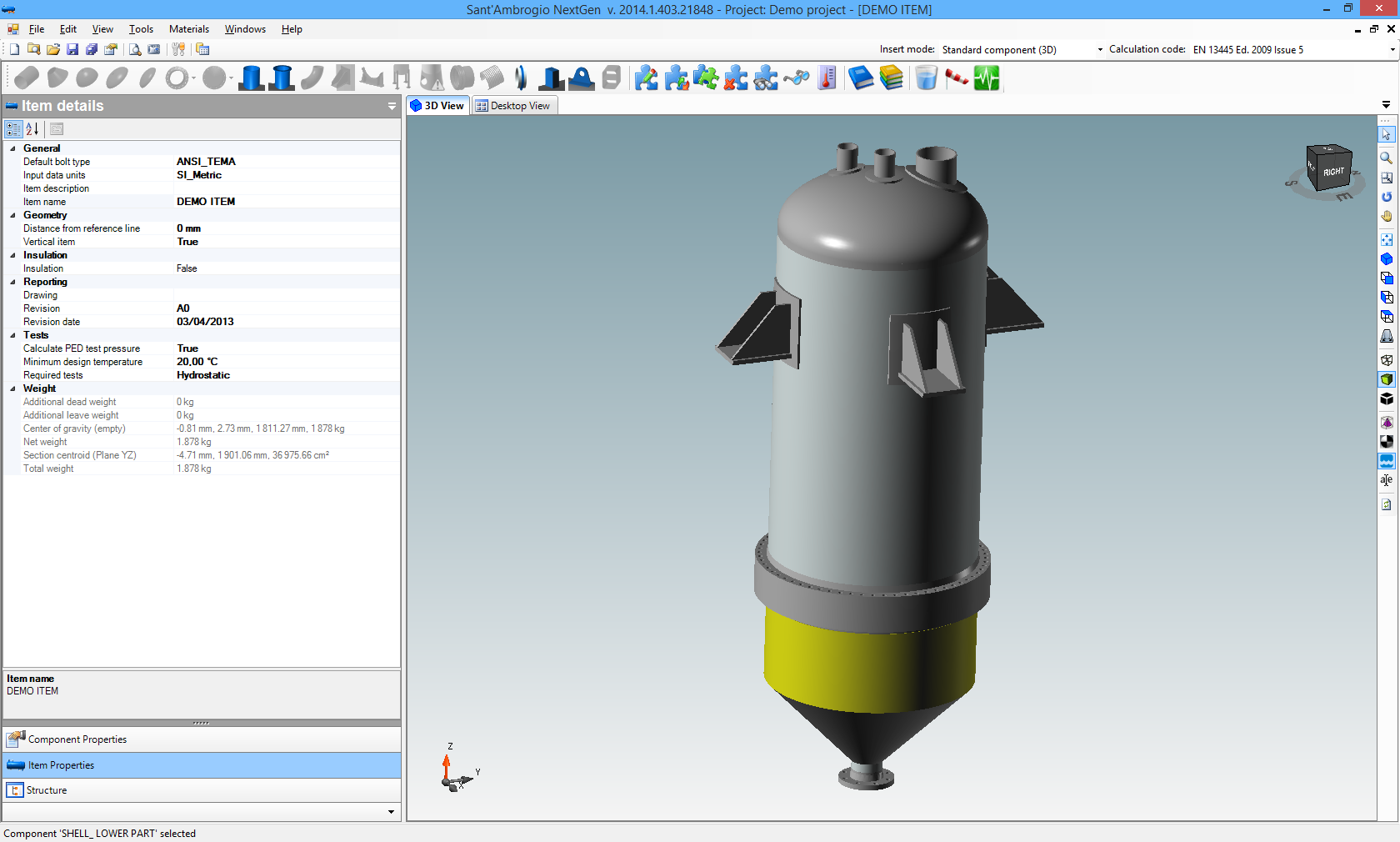

A study on designing the pressure vessel and quality check, to avoid the damage due to various conditions of nature was made. Future scope of work is mentioned clearly from current work for further study. Conclusions are made by discussing from available results. Summary of all Von-Mises plot are presented in tabulated as well as graphical form. At initial stage all options are evaluated without reinforcement and then for properly calculated nozzle reinforcement. Von-mises stress and deformation are plotted for all options under study. ANSYS workbench is used to analyze the model made in Creo Parametric 2.0 by importing it in the workbench environment, generating proper meshing, and applying boundary condition. Different nozzle location with and without reinforcement of nozzle for offset of 0 ,8 16, 24 and 32 inch from vertical centre line at central cross section with different inclination angles like 0Ëš, 15Ëš, 30Ëš and 45Ëš are modeled with Creo Parametric 2.0. PV Elite is used to determine the design of pressure vessel like the thickness of shell and nozzle data. In the present work, the importance of the effect of the discontinuity is mentioned, codes related to design of vessels and its components is discussed nozzle and vessel parameters are calculated using ASME code formulae. The junction may fail due to these high stresses. So a stress concentration is created around the opening. Distribution of stress in the juncture area and the rest will differ as nozzles cause a geometric discontinuity of the vessel wall.

Then the stress distribution is not uniform. To incorporate a nozzle on the vessel wall it is supposed to remove some amount of material from the vessel. These are having wide range of applications in several fabrication industries like steel plants in addition to the main equipment like blast furnace, Nozzles or openings are necessary in the pressure vessels to satisfy certain requirements such as inlet or outlet connections, manholes, vents and drains etc. Pressure vessels are leak proof containers.

0 kommentar(er)

0 kommentar(er)